operation jaw crusher r

2020-06-20T13:06:24+00:00

Jaw Crusher Operation Guide JXSC Machine

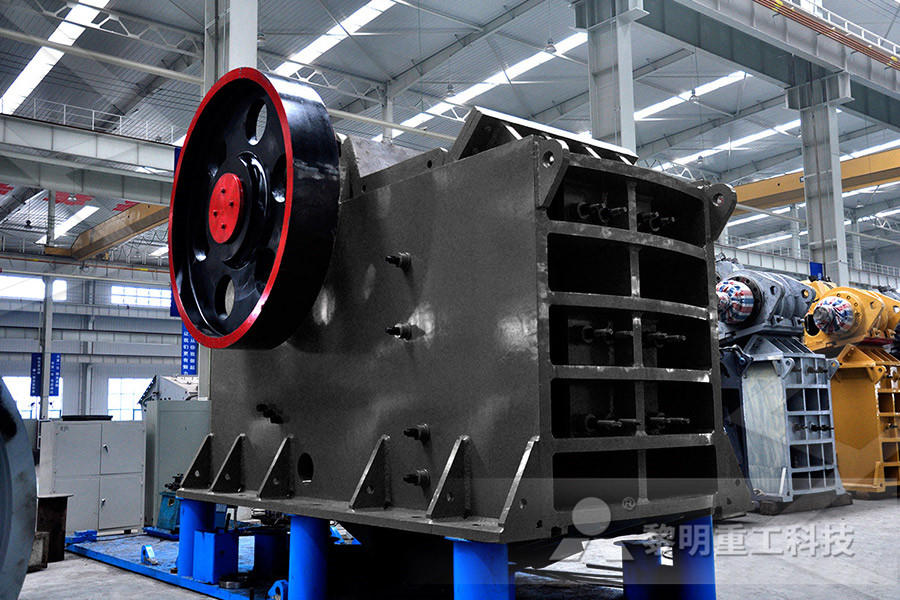

16/04/2019 Contact Now +86 Published time:16 April 2019 Correct Operation of Jaw Crusher Jaw crusher, as one of the modern crushing equipment, has a great crushing capacity and wide application Generally, working as a medium crusher, it is a standard crushing machine for the mining process and aggregate processing, quarry plant, etcI Operation of jaw crusher Proper operation is one of the important factors to ensure the continuous and normal operation of the crusher Improper operation or negligence in the process of operation is often an important cause of equipment and personal accidentsJaw crusher operation and maintenance Henan Deya operation of jaw crusher T20:04:41+00:00 Jaw Crusher Working Principle It will be noted that the motion is a rocking one When the swing jaw is rising, it is opening, at the top, during the first half of the stroke, and closing during the second half, whereas the bottom of the jaw is closing during the entire upstroke A reversal of this motion occurs during the operation of jaw crusher MC World

Jaw Crusher Operation What You Need To Know

12/01/2021 Jaw Crusher Operation Jaw crushers work on a very straightforward principle Every jaw crusher comes with 2 hardfaced heavy plates known as jaws These are used to crush large particles placed between 18/01/2019 Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other recJaw Crusher Working Principle Animation YouTubeoperation of jaw crusher T20:04:41+00:00 Jaw Crusher Working Principle It will be noted that the motion is a rocking one When the swing jaw is rising, it is opening, at the top, during the first half of the stroke, and closing during the second half, whereas the bottom of the jaw is closing during the entire upstroke A reversal of this motion occurs during the operation of jaw crusher MC World

How does a Rock Crusher Work Jaw Crusher

22/11/2021 A jaw crusher is recommended for tough, abrasive, high compressive strength materials Special machines have been designed for ores having compressive strength as high as 80,000 lbs per sq in Allsteel sectionalized frame End members are box section Deep side members of welded steel plate Deep crushing chamber assures positive nipping action Jaw crusher Advantages Optimize the crushing cavity type to make the stroke at the bottom of the crushing cavity larger, the material handling capacity is stronger, and the crushing efficiency is greatly improved Modular design is adopted to save time and installation cost, and minimize onsite construction work The core rotating parts adopt highquality casting and forging parts to What is a Jaw Crusher Advantages, Types, Parts and Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, Jaw Crusher With Different Models

C Series jaw crushers

known traditional jaw crusher range that is designed for stationary as well as mobile applications (C80, C100, C3054, C120, C125, C140, C150, C160, C200) The second range is designed specifically to meet the needs of small to medium size mobile crushing (C96, C106, C116) All C Series crushers are designed to crush very hard rock Whatever your crushing needs – from Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy maintenanceJaw Crushers MEKA Crushing Screening PlantsMediumsized jaw crusher in operation in underground mine for crushing runofmine (ROM) ore before transferring to the surface The gyratory crusher consists of a long, conical, hard steel crushing element suspended from the top It rotates and sweeps out in a conical path within the round, hard, fixed crushing chamber (Fig 1311) The maximum crushing action is created by Crusher an overview ScienceDirect Topics

Jaw Crusher Machine YouTube

22/11/2013 Special Weaves Product16/04/2019 Jaw crusher, as one of the modern crushing equipment, has a great crushing capacity and wide application Generally, working as a medium crusher, it is a standard crushing machine for the mining process and Jaw Crusher Operation Guide JXSC Machine12/01/2021 Jaw Crusher Operation Jaw crushers work on a very straightforward principle Every jaw crusher comes with 2 hardfaced heavy plates known as jaws These are used to crush large particles placed between Jaw Crusher Operation What You Need To Know

Operation Procedure of Jaw Crusher Luoyang Dahua

Operation Procedure of Jaw Crusher author:dahua time: Jaw crusher is a common used crushing machine in ore production Therefore, to know its operation procedure is helpful to enhance the crushing efficiency to some extent Following is the procedure introduced by Luoyang Dahua: 1 Often check the discharging situation, if found it is blocked, should clean in MBMMLLC Jaw crusher maintenance and operation video Apr 1 2015 We wanted to make a quick and easy instruction video for our jaw crusher Included are instructions for jaw plate removal and replacement greasing jaw gap adjustment belt tensioning and more If you have purchased one of our jaw crushers and have any questions after watching this video feel free operation jaw crushers praediafr01/04/2015 We wanted to make a quick and easy instruction video for our jaw crusher Included are instructions for jaw plate removal and replacement, greasing, jaw gapMBMMLLC: Jaw crusher maintenance and operation video

HSE Quarries Safe operation and use of mobile jaw crushers

The operation of the crusher catches being struck by any reinforcing bar as it Being pulled into the crushing chamber when attempting to pull out contaminants (eg reinforcing bar) Struck by the loader bucket if the access platform is within the working radius of the loading machine (for 360 degree excavators) Falling if adequate guardrails and access arrangements are not provided 22/11/2021 A jaw crusher is recommended for tough, abrasive, high compressive strength materials Special machines have been designed for ores having compressive strength as high as 80,000 lbs per sq in Allsteel sectionalized frame End members are box section Deep side members of welded steel plate Deep crushing chamber assures positive nipping action How does a Rock Crusher Work Jaw CrusherDOVE Jaw Rock Crusher, mining operation DOVE JAW CRUSHER FEATURES: High tonnage capacity of up to 1000 Tons/ Hour, and low operating cost Designed for toughest rock material, with compressive strength of up to 320 MPa Supplied for Primary coarse crushing and secondary Fine crushing, within the rock reduction plant Wide range of closed side setting adjustment Jaw Crusher Crushing Plant Hard Rock Mining Equipment

Jaw Crusher Primary Crusher in Mining Aggregate JXSC

Jaw crusher parts that contain frame, movable and stationary plate, bearing, eccentric shaft, toggle jaw, flywheel, eccentric shaft, Then the crusher machine stops operation, thus avoiding the damage of the whole machine The toggle plate and the toggle plate spacer adopt the rolling contact model which less attrition under normal use It just needs smear a layer of grease on working of jaw crushers videos Newest Crusher A jaw crusher uses compressive force for breaking of particle This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates A jaw or toggle crusher Are you looking for the video pictures of jaw crushers operations to sale orecrusingplant com or consulting problem working of jaw crushers videos