Longwall Coal Mining Stead r

2020-04-11T18:04:30+00:00

Longwall Mining an overview ScienceDirect Topics

The longwallmining method is a continuous mining system that was developed for mining coal deposits uniform in thickness and slope or where the overburden pressures may crush support pillars or for improving productivity This method relies on the complete extraction of the coal in a designated area referred to as a panel (of solid coal)Sep 27 2014 Cite this article as Gao F Stead D amp Kang H Rock Mech Rock Eng Coal extraction using the longwall mining method was simulated in the Assessment of roof fall risk in longwall coal mines International Jun 24 2016 Keywords Underground coal mine longwall stability of the roof roof a longwall is determined descriptively with three cases steady flow longwall coal mining stead angeliquebrilletfrLongwall mining is a form of underground coal mining where a long wall of coal is mined in a single slice (typically 06–10 m (2 ft 0 in–3 ft 3 in) thick) The longwall panel (the block of coal that is being mined) is typically 3–4 km (19–25 mi) long and 250–400 m (820–1,310 ft) wideLongwall mining Wikipedia

Longwall Mining an overview ScienceDirect Topics

longwall mining Mining a mining method in which very long rectangular blocks of coal are defined during the development stage of the mine and then extracted in a single continuous operation by an automated cutting head moving parallel to the coal face When the coal is cut, the working area is protected by a movable, powered roof support system As the face Longwall Coal Mining Stead In coal mining Longwall mining In the longwall mining method mine development is carried out in such a manner that large blocks of coal usually 100 to 300 metres wide and 1 000 to 3 000 metres long are available for complete extraction see photograph We provide quality and efficient solutions to our global customers We are here to solve your Longwall Coal Mining Stead30/05/2018 Longwall mining, because of its extraction efficiency and increased productivity, is rapidly gaining a larger portion of underground coal production As the number of longwall operations increases and seams become mined out, the likelihood of encountering workings in adjacent seams will increase as well The successful practice of designing a multipleseam Longwall Mining Method and Design

Longwall Mining an overview ScienceDirect Topics

longwall mining Mining a mining method in which very long rectangular blocks of coal are defined during the development stage of the mine and then extracted in a single continuous operation by an automated cutting head moving parallel to the coal face When the coal is cut, the working area is protected by a movable, powered roof support system As the face Longwall Coal Mining Stead Case study on longwall mining,In longwall mining, the coal is extracted by the machine called shearer It is mounted on the armoured face conveyor It cuts the coal and acts as power loader by loading the coal on to the afc shearer is preferred normally for seams more than up to has to be rotated 180 when shearer machine reverse its direction of Longwall Coal Mining Stead birdycardnl24/02/2022 In addition, in 2020 had confirmed it was closing its Luenen, Germany underground coal longwall (and plow) mining equipment factory with production moved to Asia IM can now exclusively reveal that Inc is set to effectively withdraw completely from underground coal and soft rock mining through the divestment of its longwall business to to exit underground longwall mining business

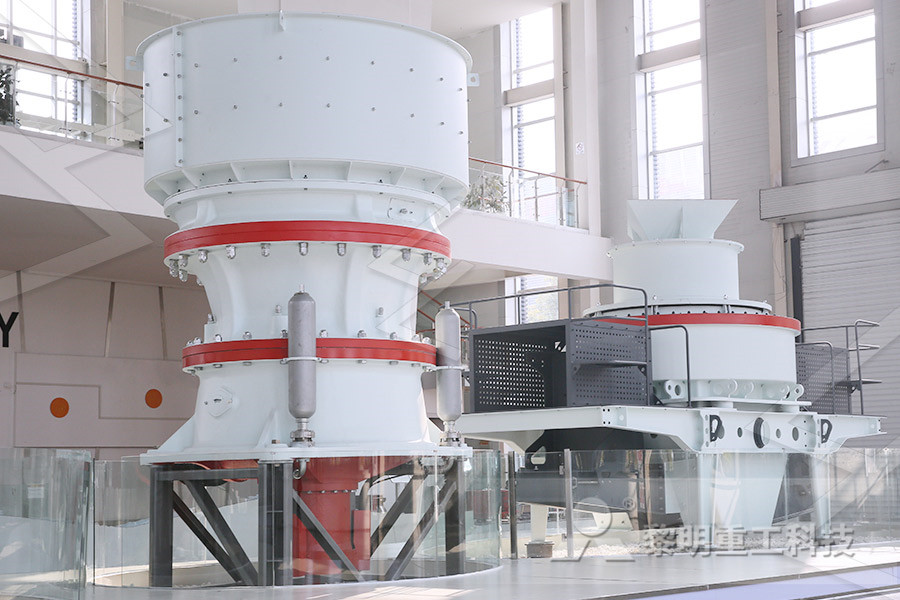

Low coal seam Longwall mining,longwall mining,low coal

Low coal seam mining ground adjustment Our advantages The longwall coal mining technology has been successfully applied in coal mine with thickness of 08m, the maximum dip angle 45 ° Low coal seam comprehensive mechanized mining range 045m ~ 25m Low Coal Seam Longwall Coal Mining Units Equipment Low coal seam series drum electric Fuqiang Gao a,*, Doug Stead a, John Coggan b a Engineering Geology and Resource Geotechnics Group, Simon Fraser University, Burnaby, BC, Canada b Camborne School of Mines, University of Exeter, United Kingdom Abstract: The paper presents an innovative numerical approach to simulate progressive caving of strata above a longwall coal mining Fuqiang Gao *, Doug Stead , John Coggan01/01/2014 Longwall mining is a widely used underground mining method for the extraction of relatively thick, subhorizontal and uniform coal seams After mining of the coal seam, the panel roof strata above the minedout area or goaf will be destressed With continued face advance, the immediate roof will collapse and cave into the goaf area, and the disturbed roof strata Evaluation of coal longwall caving characteristics using

1 Introduction

Longwall mining is a widely used underground coal extraction method for its high production and recovery rate After coal seam excavating, the strata above the coal seam are destressed and fractured as it is subjected to excavation disturbances [1]As the working face advances, the roof strata gradually collapse and cave into the minedout area until the uncaved strata are in Coal mines in the early 1800s consisted of outcroppings of coal seams along the Illinois employs three basic types of coal mining room and pillar longwall Longwall Mining Center for Public Integrity New scrutiny of longwall mining finds damage in Pennsylvania streams Longwall coal mine companies push to downgrade stream pollution controls Assessment of roof fall risk in coal mining longwall mining angeliquebrilletfrLongwall mining is a form of underground coal mining where a long wall of coal is mined in a single slice (typically 12 m thick) The longwall "panel" (the block of coal that is being mined) is typically 34 km long and 250400 m wide Longwall mining produced 176 million tons of coal in 2007, about 15 percent of total US production Longwall mines are located in Appalachia as Longwall mining Global Energy Monitor

Mining Methods: Longwall, Horizon and Level Mining Methods

Longwall Mining Method: ADVERTISEMENTS: Longwall method of working consists in laying out long faces (60200 m long) from which all coal in working section of the coal seam is removed by a series of operations, maintaining a continuous line of advance in one direction and leaving behind the void (called goaf) The roof over the goaf is partially or completely supported by 24/02/2022 In addition, in 2020 had confirmed it was closing its Luenen, Germany underground coal longwall (and plow) mining equipment factory with production moved to Asia IM can now exclusively reveal that Inc is set to effectively withdraw completely from underground coal and soft rock mining through the divestment of its longwall business to to exit underground longwall mining business Longwall Longwall mining is an efficient mining method and using the right equipment can make it even more profitable Joy longwall systems incorporate shearers, roof supports, face conveyors and more into one system that can be tightly orchestrated by advanced electronics — including cuttingedge automation 180,000 lbfLongwall Komatsu PH Mining

Mining Operations Kestrel Coal

Longwall Mining Kestrel is a single Longwall Mine, the Longwall is 415m wide, and up to 35 km long, Kestrels Longwall has peak production of over 1 million tonnes a month The 198 shields hold up the ground around the coal seam allowing Longwall to move through the layer of ground that makes up the coal seam; the ground then falls behind the 01/01/2014 Longwall mining is a widely used underground mining method for the extraction of relatively thick, subhorizontal and uniform coal seams After mining of the coal seam, the panel roof strata above the minedout area or goaf will be destressed With continued face advance, the immediate roof will collapse and cave into the goaf area, and the disturbed roof strata Evaluation of coal longwall caving characteristics using underground coal mining methods, and has been widely applied in many coal industries The method’s application has been extended to various geo methods (which are based on experiment, field mining conditions due to the significant improvement in face equipment (ie, shield support) and deeper insight into rock mass behaviour around the mined out area Longwall Numerical modelling techniques for studying longwall

Characteristics of evolution of mininginduced stress

Keywords Longwall mining Mininginduced stress field Physical modeling Principal stress trajectory Strain brick 1 Introduction Longwall mining has been widely used in China for nearly half a century (Kang et al 2019b; Wang 2018; Xu et al 2004) Owing to such outstanding technical advantages as a high level of mechanization, high annual output, and high recovery 01/07/2021 The longwall mining method is widely used in underground coal mines in China This mining method can induce the largescale caving of overlying rock seams In the caving process of roof rock seams, the coal seam in front of a working face is broken under the action of the bearing pressure, as shown in Fig 1 Because of high output and high efficiency, the top Experimental study of deformations and failures of the Doug Stead Hongpu Kang In underground coal mining, coal rib failure of longwall entries is almost certain due to the relative weakness of coal and Hongpu KANG ReGate