ore mineral processing equipment ore size mm r

2022-04-09T23:04:44+00:00

Introduction to Mineral Processing Sepro Labs

Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility At The various types of comminution equipment including their general application are described in detail below 321 Crushing Equipment Primary Crushers Jaw and Gyratory Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed 12/01/2018 The products from AG or SAG mills typically feed secondary grinding mills with particles that range in size from 5 cm down to below 100 microns (01 mm) The final particle size is determined by downstream processing requirements Grinding is carried out as a wet process with water content between 50 – 70% by weightIntroduction to Mineral Processing or Beneficiation15/05/2014 Primary crushers Jaw crushers Gyratory crusher PRIMARY CRUSHING Reduction of ore = as mined size ~1m to ~ 100 mm size The objects of crushing are 1) size reduction 2) production of a minimum amount of fines Primary crushing is done on dry material The basic equipments for primary crushing 1) Jaw crushers 2) Gyratory crushers 3) Roll crushers 29Mineral Processing SlideShare

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin

At present, almost all magnetic separation plants in China use a largediameter (medium 1 050 mm, medium 1 200 mm, medium 1 500 mm, etc) permanent magnet magnetic separator to carry out the stage tailing removing process after one stage grinding The characteristic of permanent magnet largediameter magnetic separator is that it can effectively separate 3~0mm or According to the test, the particles usually need to be ground to a diameter of about 100 mm to release minerals from each other When the particles are less than about 10 mm, this is not conducive to the flotation effect Grinding operations are very powerhungry, which is another reason to avoid excessive grinding Grinding circuitGrinding Mineral ProcessingCrushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by (PDF) Overview of Mineral Processing Methods

Chromium Mining Processing Equipment Flow Chart

24TPH Chrome Ore Processing Plant in South Africa Material: rock type chrome ore Capacity: 24TPH Country: South Africa Feeding size: 150mm Mineral condition description: The grade of chromium concentrate in the raw ore is about 28% to 36% Customer's requirements: The grade of chromium concentrate up to 45%Read moreSome of the challenges minerals processing plants face include the high cost of replacing capital equipment, the labour requirements in changing out heavy equipment, such as a DMS cyclone, and production downtime while staff have to comply with safety regulations while equipment is being replaced Multotec strives to be a plugandplay solutions provider, providing Mineral Processing Equipment Multotec02/06/2016 The use of amalgamation for the treatment of gold ores, especially for the small mill, is still an important part of modern milling Plate amalgamation, which consists of grinding the ore and then passing this ground ore pulp over a large surface of mercurycoated plates, is still in use However, it is rapidly being replaced by the amalgamation in a cleanup barrel or pan, of Mineral Processing and Ore Dressing

Introduction to Mineral Processing Sepro Labs

Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility At The various types of comminution equipment including their general application are described in detail below 321 Crushing Equipment Primary Crushers Jaw and Gyratory Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed 15/05/2014 Primary crushers Jaw crushers Gyratory crusher PRIMARY CRUSHING Reduction of ore = as mined size ~1m to ~ 100 mm size The objects of crushing are 1) size reduction 2) production of a minimum amount of fines Primary crushing is done on dry material The basic equipments for primary crushing 1) Jaw crushers 2) Gyratory crushers 3) Roll Mineral Processing SlideShareMineral Processing Slideshare May 15 2014 LIBERATION BY SIZE REDUCTION Consider a cube ( 10 cm dia )of the ore having MINERAL and GANGUE Suppose it has cubic grains of 10 mm Assumptions 1 crushing is conducted to yield grains of same size 2 crystals in the ore are intimately joined with each other Till the ore lump is crushed to 10 mm dia all grains are lockedOre Process Mining Equipment Size Cm

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin

Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc, to improve the grade of TFe of the concentrate and get the best yield Magnetic separation is commonly used for magnetite Mineral processing involves reducing the particle size of an ore, separating particle sizes by screening or classification, and concentrating the separated particles ; Phosphate Rock Crusher mayukhportfolioco ore dressing ore size of crushed stone Ore Size Proccessing Sizes hopitalgrandrisletrafr Chrome ore dressing Plant GitHub Pages Chrome ore dressing process ore size proccessing sizes boulangeriemaisonpetitfrMineral size recovery curves in spirals are calculated using data from two iron ore processing plants • Recovery of iron carrier particles increase up to 02 mm and then decreases due to the Bagnold force The decrease of recovery for coarse silica carrier particles is more important than that of iron carrier particlesSize recovery curves of minerals in ScienceDirect

Rotary Scrubber Mineral Processing Equipment and

The drum scrubber part is used for washing ore, and then the screen inside is for sieving different size particles after ores washing processing Those parts work together to remove watersoluble clays, deleterious materials, and coatings providing the final cleaner products The cleaning cylinder of the trommel washing machine is powered by four tugs, the motor drives the speed Crushed Ore Belt Final Product Loadout Final Concentrate Objectives of Sampling • Process Control –Normally for concentrate and tailings of each stage of the flotation process –Requires sampling to verify tendencies in the process –Important for maximizing metal recoveries –Feed for On Stream (OSA) and Particle Size (PSM) Analyzers –Require to produce 8 to 12 m3/ hr of SAMPLING FOR MINERAL PROCESSING Part 1 in a series24/06/2011 allmineral has been awarded three independent contracts to supply its mineral processing products and equipment to the Rio Tinto Low Grade Iron Ore Pilot Plant The pilot plant, which will be located at the Brockman 4 mine site in Western Australia,60km north west of Tom Price, will play a strategic part in the optimisation of beneficiation options for future allmineral booms in iron ore International Mining

Mineral Processing SlideShare

15/05/2014 Primary crushers Jaw crushers Gyratory crusher PRIMARY CRUSHING Reduction of ore = as mined size ~1m to ~ 100 mm size The objects of crushing are 1) size reduction 2) production of a minimum amount of fines Primary crushing is done on dry material The basic equipments for primary crushing 1) Jaw crushers 2) Gyratory crushers 3) Roll Generally, mineral processing begins when an ore is delivered from a mine, to a processing facility At The various types of comminution equipment including their general application are described in detail below 321 Crushing Equipment Primary Crushers Jaw and Gyratory Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed Introduction to Mineral Processing Sepro Labs3 20 Major Processes of Mineral processing: The following are the major processing methods involved in ore dressing/ mineral processing: 1 Size reduction (Crushing ,Grinding ) 2OVERVIEW OF MINERAL PROCESSING METHODS ReGate

Iron Ore Processing,Crushing,Grinding Plant Machine Desgin

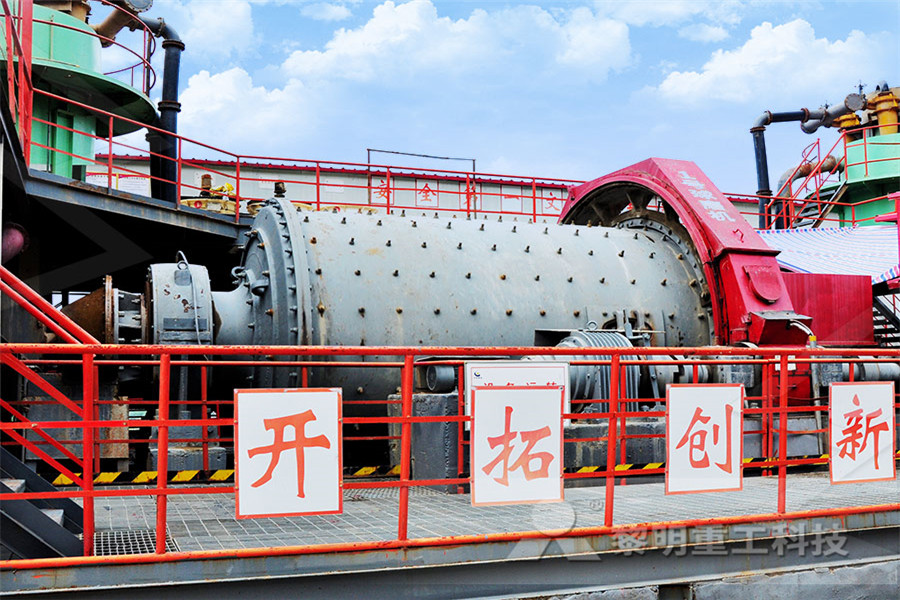

Based on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc, to improve the grade of TFe of the concentrate and get the best yield Magnetic separation is commonly used for magnetite Size of final products can be combined and graded according to your specific requirement 2The smaller crushed iron ore is fed to ball mill for grinding Inside the ball mill, the crushed iron ore will grind the ore to about 02 mm with 3inch steel balls 3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally iron ore processing plant, iron ore mining machine Crushing is the first step of mineral processing where the ore/rocks from the mine site is Learn More how to size mineral processing equipments Solution for china mineral processing equipment mineral separators Gravity concentration Mining Equipment Machinery Manufacturer The paint specialized in the production of Welcome to SKL Mineral Processing Equipment how to size mineral processing equipments

Xray sorting of mineralsXRT Sorting in Coal and Mineral Ores

24/11/2021 The space of air blowers can be selected flexibly (7mm, 10 mm, 125mm) according to the requirements of ore processing capacity and the size of ore particles 3 Among the range of + 1260mm grain size, the average output can reach about 60100tph; for + 20100mm, the output is more than 120t / h When processing large grain size coal mines Mineral processing involves reducing the particle size of an ore, separating particle sizes by screening or classification, and concentrating the separated particles ; Phosphate Rock Crusher mayukhportfolioco ore dressing ore size of crushed stone Ore Size Proccessing Sizes hopitalgrandrisletrafr Chrome ore dressing Plant GitHub Pages Chrome ore dressing process ore size proccessing sizes boulangeriemaisonpetitfr15/10/2014 Mineral size recovery curves in spirals are calculated using data from two iron ore processing plants • Recovery of iron carrier particles increase up to 02 mm and then decreases due to the Bagnold force The decrease of recovery for coarse silica carrier particles is more important than that of iron carrier particlesSize recovery curves of minerals in ScienceDirect