cement mill plant environment r

2020-05-25T17:05:21+00:00

Cement Mill Plant Environment lerepitfr

Environment Antea Cement Emission levels in ANTEA Cement Plant refer to standard conditions dry gas at a temperature of 273 K, and a pressure of 1 013 K Particulate Matter There are two sources of dust in cement plant, respectively Point source dust is the total of the particulates emitted from the stacks (kiln, cement mill, coal mill, and Cement Mill Plant Environment Air pollution from Cement manufacturing is becoming an environmental problem worldwide Recent studies determine relationship between cement air pollution and human health diseases Pollutants from cement plants are causing harmful effects on human health The following timeline shows some of the major steps in our sustainability Cement Mill Plant Environment mobilite33frThe main processing units are crushers unit, raw mill, homogenizing plant, kiln system, cement mill and packing plant Get Price Health Risks Associated With Workers in Cement Factories substances in the cement mill environment Besides cement dust various gaseous pollutants are also contributed by cement factories which cause pollution and ultimately affect human what effects does cement mill or plant have on the environment

Cement Mill Plant Environment dominiqueetromainfr

Cement Mill Plant Environment This EPD reports environmental transparency information for five cement types produced by Holcim at its Devil’s Slide, UT plant Cements are hydraulic binders and are manufactured by grinding cement clinker and other main or minor constituents into a finely ground, usually grey colored mineral powder When mixed Environment Statement Report Cement Mill – I SPM 10 45 22 78 71 53 Cement Mill –II SPM 24 87 21 18 73 53 Packing plant provide sufficient fund for Environmental protection at our cement plant and Captive Power Plant PART I Any other particulars in respect of environment protection and abatement of pollutionCement Mill Plant Environment bourgetpassionfrCement kilns, with their high flame temperatures, are sometimes used to burn waste oils, solvents, and other organic wastes These practices can result in the release of toxic metals and organics Cement plants are not normally designed to burn wastes; but if such burning is contemplated, the technical and environmental acceptability need to beEnvironmental Guidelines for Cement Manufacturing

Impacts of Cement Industry on Environment An Overview

Emissions from Cement manufacturing are one of the major contributors in global warming and climate change Cement belo ngs to the most often used building materials and its production isA Review On Environmental and Health Impacts Of Cement Manufacturing Emissions Shraddha Mishra, Dr Nehal Anwar Siddiqui Health, Safety Environment, University of Petroleum Energy Studies, Dehradun, Uttarakhand, India Abstract: Climate change is considered as major environmental challenge for the world Emissions from cement manufacturing are one of the A Review On Environmental and Health Impacts Of Cement The cement production technologies in use cause extensive power consumption, gas emissions, noise pollution environmental heating and emissions of fuel (CO2, NOXSO2and CO) from the kiln and precalciner These are the major sources of environmental pollution in the cement industry to the best possible extent 11 Re aim and methodologyCement and its effect to the environment: A case study in

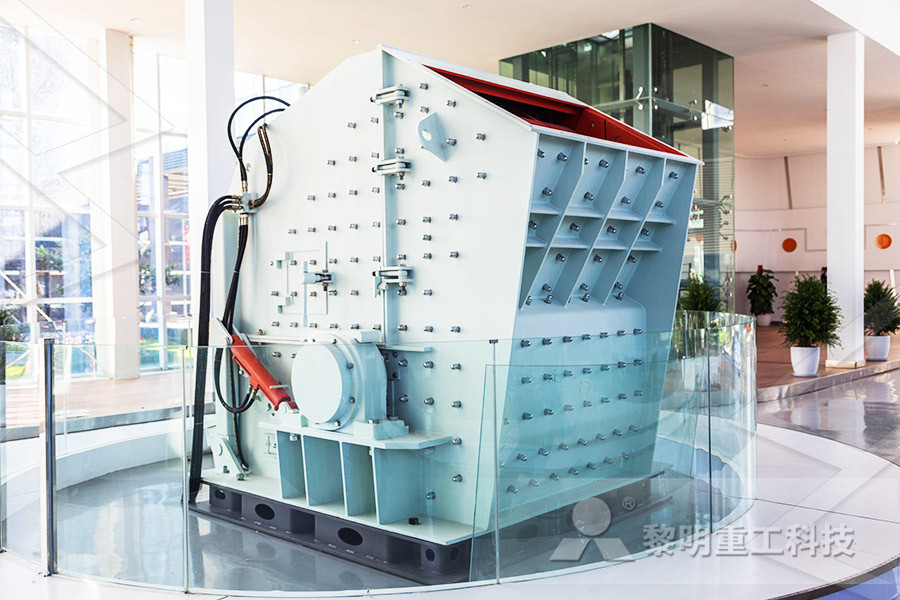

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

In the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement millCement manufacturing components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc For information on materials, including reactions in the kiln, see the ' Clinker ' pagesSalah M El Haggar, in Environmental Solutions, 2005 Cement Mill Plant EnvironmentPortland cement and the environment Portland cement is manufactured by heating limestone or chalk with clay in a rotary kiln to a high temperature (about 1450°C) to produce hard nodules of clinker that are then ground with a little gypsum in a ball mill The firing process consumes significant quantities of fuel usually coal or petroleum cokewhat effects does cement mill or plant have on the environment

Environmental Guidelines for Cement Manufacturing

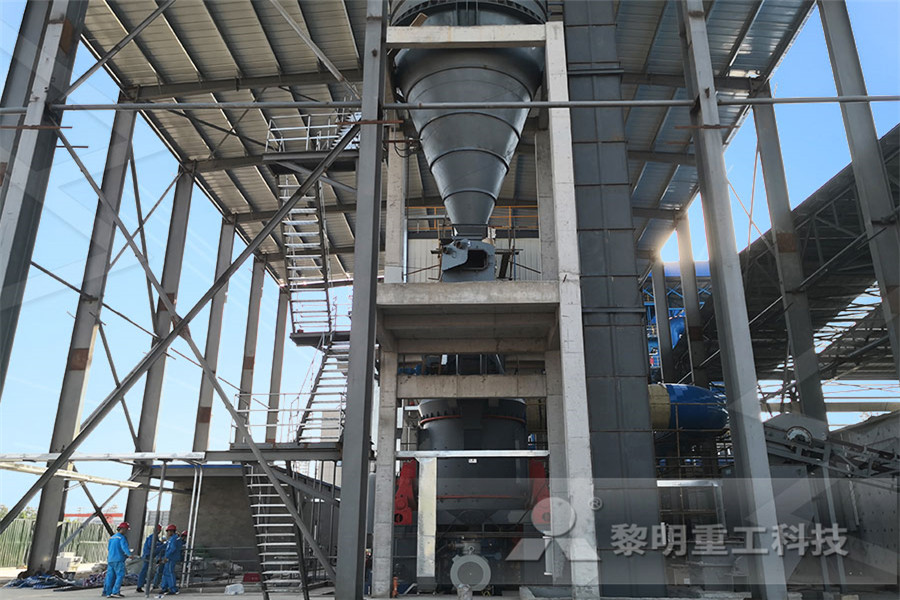

Cement kilns, with their high flame temperatures, are sometimes used to burn waste oils, solvents, and other organic wastes These practices can result in the release of toxic metals and organics Cement plants are not normally designed to burn wastes; but if such burning is contemplated, the technical and environmental acceptability need to beBuilding industry is one of the leaders in deterioration of environment by depleting resources and consuming energy or creation of waste (Stajanca and Impacts of Cement Industry on Environment An OverviewCement vertical mill reduce the environmental pollution The working process of vertical cement mill is closed and produces less noise, there is no dust or wastes or raise dust, ensure the clean working condition and less pollution In addition, vertical cement mill is required to add certain water into raw materials in the processing, which achieves the goal of saveenergy and Vertical Cement Mill, Vertical Roller Mill Cement Plant

A Review On Environmental and Health Impacts Of Cement

A Review On Environmental and Health Impacts Of Cement Manufacturing Emissions Shraddha Mishra, Dr Nehal Anwar Siddiqui Health, Safety Environment, University of Petroleum Energy Studies, Dehradun, Uttarakhand, India Abstract: Climate change is considered as major environmental challenge for the world Emissions from cement manufacturing are one of the 03/03/2022 The Lisen Cement Plant in Deyang has been in operation since 2021, and is now a subsidiary of the Southwest Cement Group, one of China’s largest producers of cement for industrial and commercial applications Southwest was fully supportive of the investment to upgrade processes at the Lisen plant As a member of the China National Material Building Dealing with dust in Deyang World CementEmission SourcesCement Mill, Clinker Silo, Fly Ash Silo, Cement Silo, Wagon Tippler, Gypsum Crushing Plant, Packing Section, etc Water Requirement175 KLD Power Requirement — 18 MW (approx) from DG Set of 125 MW and from BSEB Total cost of the project —Rs 41535 Crore iii vi Vii viii ix CONDITIONS FOR ENVIRONMENTAL CLEARANCE FOR THE Bihar Cement Plant Environment Clearance Shree Cement

Triennial Environmental Audit Boral

Cement Mill 7 DA No 8542005i Kiln 6 DA No 401112002i February 2021 Prepared By: International Environmental Consultants Pty Limited “Longmead” 700 Wombeyan Caves Road High Range NSW 2575 Boral Berrima Cement Plant – Triennial Compliance Audit 2020 Page i Table of Contents 1 Introduction 1 11 Executive Summary 1 12 Introduction 2 13 Running Plant Compliance Status of Environment Clearance of Cement Plant issued vide Letter No J11011/76/2007 IAII (I)(T), Dated: 5 th April ,2007 of M/s Dalmia Cement (Bharat) Ltd Half yearly Compliance Report (1st April 2020 to 30th September 2020) Covered Sheds Raw Mill / Kiln Bag House Ba g filters at transfer points 2 The unit shall use the high calorific Complied Running Plant Compliance Status of Environment Clearance What Effects Does Cement Mill Or Plant Have On The Environment However, we have a fairly successful track record of identifying and eventually curbing the impacts of industry on the environment For example, through policy and the improvement of new technologies, air pollution from manufacturing in England has been greatly decreased since it was at its worst Get A What Effects Does Cement Mill Or Plant Have On The Environment

Impacts of Cement Industry on Environment An Overview

Building industry is one of the leaders in deterioration of environment by depleting resources and consuming energy or creation of waste (Stajanca and All plants must have an environmental management system in place to ensure that all environmental impacts and risks are effectively managed and mitigated Integrated cement plants (incl quarries and related captive power plants), grinding stations and AFR preprocessing plants must have an EMS in place at least equivalent to ISO 14001All other Cement Environmental DirectiveWhat Effects Does Cement Mill Or Plant Have On The Environment ENVIRONMENTAL IMPACT ASSESSMENT MINI CEMEMT PLANT M/s Raksha Cements (P) Limited Extended automation Integrated solutions for cement Extended automation Integrated solutions for environment provide a foundation for the efficient Control room at Jura Cement plant, What Effects Does Cement Mill Or Plant Have On The Environment

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished CRH Canada’s Mississauga Cement Plant was one of the first cement plants in North America to implement the ISO 14001 Environmental Management System (EMS) This entails implementing monitoring and control systems to reduce environmental impact, and the Vertical Roller Mill (VRM) for slag processing is a oneofakind innovation in climate change Environment and Sustainability Updated CRH CementJSW Cement Ltd (AP), Environmental statement for the financial year ending the 31st March 2020 6 control the stack emission levels below 30 mg/Nm³ JSW Cement Ltd is the first company in the Indian Cement Industry to install this type of technology Raw mill/ Kiln stack is 140 M high with continuous online stack monitoring system Average YEAR 20192020 JSW Cement

8048b47d6c624b3fb53b97da41f161a6

In order to make the plant Environment friendly, Vasavadatta Cement has taken the Pollution Control measures by installing Bag House for Raw mill/Kiln, ESPs for Grate Cooler; Bag filter for cement mill, lime stone crushing, Blending silo, Cement silo, Clinker stockpile, Raw mill hoppers, Cement mill hoppers, Coal mill, Coal weigh feeders, Fine coal bin Packing plant 10/12/2019 Cement dry ball mill has good sealing performance, environmental protection, simple maintenance, safe and reliable operation The equipment of ball mill used in cement plant includes vertical cement mill, roller press and ball mill, etc The cement ball mill in cement plant is usually divided into 24 silos, the most representative of which are the “new Cement Ball Mill JXSC MachineCement Plant information for Gaborone Mill can be found below For full access to the database, purchase The Global Cement Report™, 14th Edition PurchaseCement plant information for PPC Botswana Gaborone Mill