iron ore mining processes r

2021-01-18T13:01:07+00:00

Iron Mining Process Minnesota Iron

Iron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into small pieces Transportation The taconite pieces are scooped up by electric shovelsMINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scale The float ore area is dug up Iron Ore Mining Techniques Metal Extraction14/03/2018 When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This step prevents overloading the The Six Main Steps of Iron Ore Processing Multotec Canada

Mining of Iron Ores – IspatGuru

14/03/2014 The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse Iron ore crushing plant iron ore beneficiation and miningProcess Flow Diagram Of Iron Ore Mining And Benifeciation 23/10/2017 It has to be derived from iron ore that occurs near the surface when mining Then the iron derived after a long processing in the blast furnace is handed over to the iron and steel industry to make a huge amount of useful materials Most of the iron, however, is used in the construction industry In fact, the entire construction sector is highly dependent on the Iron The StepbyStep Process of Producing Iron from Iron Ore

Iron Ore Processing Prominer (Shanghai) Mining

Iron Ore Processing Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore14/03/2014 The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore Mining of Iron Ores – IspatGuru21/06/2018 Regions in which iron ore has formed over millions of years (eg through volcanism) and can be mined economically are also referred to as iron ore deposits Especially many ore deposits can be found in countries such as China, Australia, Brazil, India and Russia These countries account for around 85 % of the total global iron ore mining volumeIron ore mining and dressing tecscience

Iron Ore: From Mining to Processing to Dust Control

Mining iron ore typically involves finding a fertile site, drilling and blasting the ore, and then transporting it to the primary crusher for processing Crushed ore is sorted over screens and resized to different specifications (lump and refined products) After the processing, a stacker builds a stockpile in the stockyards Then, a reclaimer picks up the ore from the stockpiles and Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore The beneficiation process should Iron Ore Processing Prominer (Shanghai) Mining Iron ore mining process and iron ore mining equipments Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse More (PDF) Life iron ore mining processes uabpu

Iron Ore Mining Process Flow Chart Pdf > flowchart of

16/05/2021 Introduction iron ore mining process flow including iron ore crushing basic iron ore processing flow chaBeneficiation is a process which removes the gang particle like Alumina, Silica from the Iron Ore Iron ore is converted into various types of iron through several processeshe most common process is the use of a blast furnace to produce pig iron which is Iron ore is an important raw material for iron and steel production enterprises After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore) It is the mineral aggregates that contain iron or iron compounds which can be used economically Production Process of Iron Ore Iron Ore,Production Process of Iron Ore,Iron Ore Iron Ore production in the Pilbara Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality control are fundamental to the process Iron Iron Ore production in the Pilbara Rio Tinto

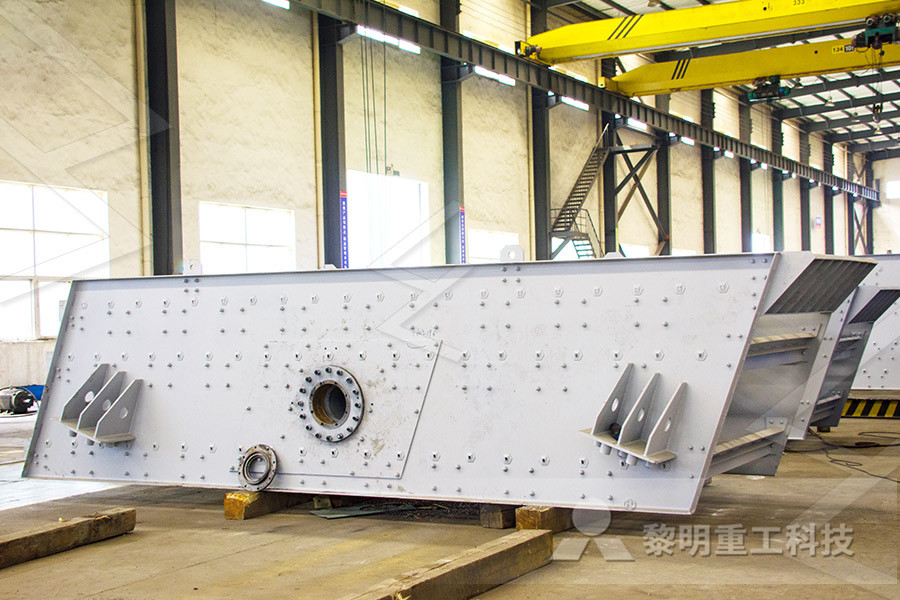

Iron or mining processing equipment Schenck Process

The harsh environment and varied bulk material sizes in iron ore mining and processing demand technology that’s both durable and can be adjusted to your unique needs Working in close partnership with the world’s largest iron ore producers over the past 20+ years, we’ve developed a range of solutions that go the extra mile, standing up to extreme site conditions while 23/02/2022 Numerous iron ore mining companies were forced to halt operations as a result of the crunch, including Venture Minerals’ Riley mine in Tasmania, Mount Gibson Iron’s Shine project in Western Iron ore’s uncomfortable truth Australian MiningIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity Iron Ore Processing Prominer (Shanghai) Mining

iron ore mining processes uabpu

Iron ore mining process and iron ore mining equipments Mining and processing of iron ore involves coarse crushing and screening Iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening This is usually so efficient that lower grade ore can be treated especially when the magnetite is quite coarse More (PDF) Life Iron ore mining process and iron ore mining The middlings produced by three processes are moved to screening process The tailings of wet magnetic separation will be discharged directly Grinding and fine crushing After the second crushing, iron ore particles are moved to secondary crushing and the first ball mill grinding With fine ore particles, it is more efficient to upgrade processes of iron ore mining rossrenovationfr11/03/2009 Iron Ore Mining Industry Business processes can offer Implementation Challenges across all SAP Modules like Sales and Distribution, FI and CO, HR, Material Management, Production Planning, Quality Management, Plant Maintenance and EHS Sales and Distribution – Regular Sale Order Process (with or without Contract) could be implementedIron Ore Mining Business Process SAP Solution SAP Blogs

(PDF) Life cycle assessment of iron ore mining and processing

Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in 01/01/2015 Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter using SimaPro LCA software as a case study The environmental impacts considered in the study were embodied energy and greenhouse gas (GHG) emissions, while Life cycle assessment of iron ore mining and processing Iron ore mining Schenck Process Iron ore mining Working with Iron Ore industry to improve recovery Schenck Process has been active in iron ore mining for more Live Chat » iron ore mining processes Introduction iron ore mining process flow including iron ore crushing, magnetic separation, grinding, classification and flotation, and iron ore mining equipments mining processes of iron ore mepsystemfr

Iron ore mining YouTube

08/10/2011 Iron Ore mining in the Plibara region of Western Australia near Newman The Mt Whaleback, Yandi, and Area C mines are shown01/12/2015 Iron ore surface mining product system21 Case study This paper presents a survey of environmental aspects and impacts related to the iron ore life cycle based on primary data of the process used by Samarco Mineração in its plant in Germano, Iron Quadrangle/BrazilA Life Cycle Assessment study of iron ore mining Introduction Iron ore Iron ore is rock containing enough iron content, and in sufficient volume and accessibility to mining and transportation to be able to be economically mined Iron in ore iron is most commonly found in the form of magnetite (Fe 3 O 4), hematite (Fe 2 O 3), goethite (FeO(OH)), limonite (FeO(OH)n(H 2 O)) or siderite (FeCO 3)Roughly 98% of iron ore on the Environmental impact of iron ore mining Wikipedia