manufacture of cement by dry processes r

2023-08-08T11:08:12+00:00

Dry Process for Manufacturing of Cement GharPedia

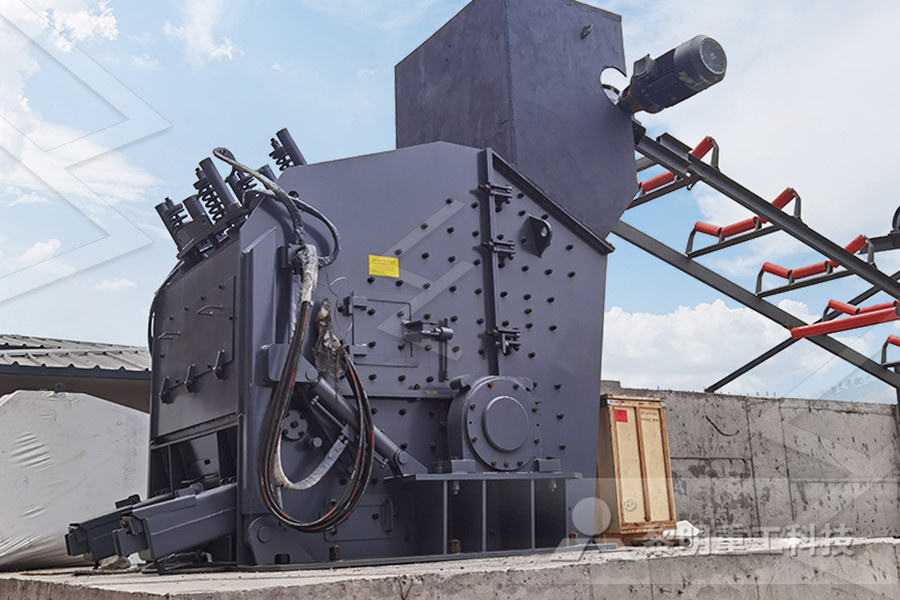

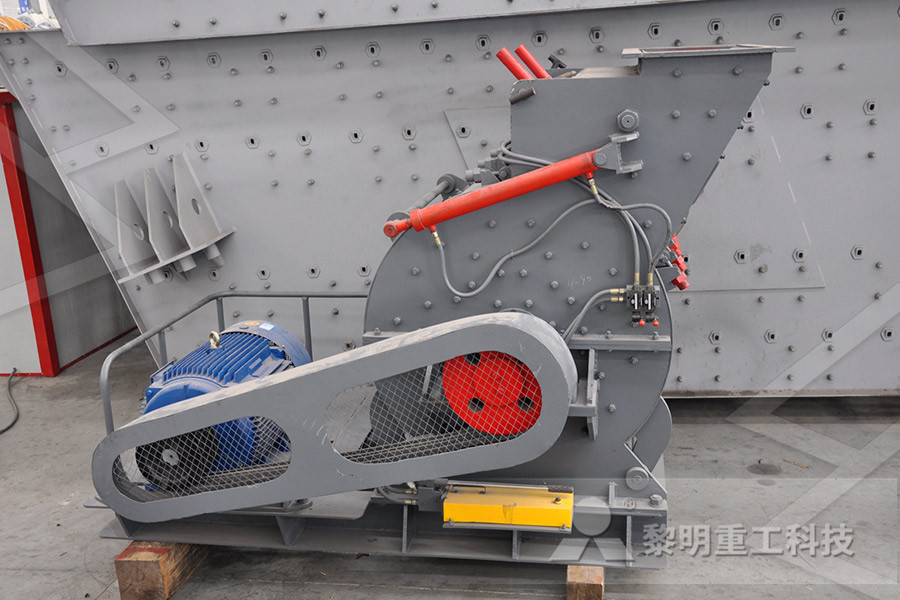

In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill The raw materials are dried and reduced in size to a fine powder in to grinding mill The dry powder is called the raw meal The raw meal is pumped into a blending silo Adjustment in the proportion of the materials required for the Now let’s know the manufacturing of cement by the dry process DRY PROCESS When the available raw materials are quite hard, then this process is used The cement by this process can be prepared by using the following operations: Mixing of raw materials Burning and GrindingManufacturing of Cement By Dry and Wet Process Expert Civil29/10/2019 The key symbol of new dry process cement production technology is that it adopts a new dry process cement kiln(general name for suspended prewarm machine and predecomposition kiln) New dry process cement production kiln is the upgrading kiln type for old dry process cement kiln(also called dry hollow kiln) New dry process cement Dry Process Of Cement Manufacturing\Dry Process Of Cement

Dry process of cement we civil engineers

24/08/2018 these are two different processes of manufacturing cement wet process minerals are wet ground (by adding water) to form a slurry and then dried, dry process minerals are dry ground to form a powder like substanceboth the processes are in use and have their own advantages and disadvantageswhile in wet process grinding is easier,in dry process 16/01/2019 There are 2 types of method of manufacturing of cement bag in this video we can see manufacturing of cement by dry processManufacturing of Cement by Dry Process, #civilcafe YouTubeAll the cement plants set up after 1980 use the dry process for the manufacture of cement In this process, the calcareous materials such as limestone are crushed and stored in silos or storage tanks The argillaceous material such as clay is thoroughly mixed with water in a container known as the wash millCement Manufacturing Process: How the Cement is Made?

manufacture of cement by dry processes

Manufacture Of Cement By Dry Process Flow Chart Dry process cement Britannica Other articles where Dry process is discussed: cement: Manufacture of cement: are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry powder, or ground dry and then Manufacture of Portland Cement Materials and Process Comparison between wet and dry process Wet process Dry process 1 Moisture content of the slurry is 3550% 1 Moisture content of the pellets is 12% 2 Size of the kiln needed to manufacture the cement is bigger 2 Size of the kiln needed to manufacture the cement is smaller 3 The amount of heat required Manufacture of cement by dry process pdfFig: Manufacture of Cement by Dry Process b) Wet Process The raw materials are firstly crushed and made into powdered form and stored in silos The clay is then washed in washing mills to remove adhering organic matters found in clay The powdered limestone and water washed clay are sent to flow in the channels and transfer to grinding mills where they are Manufacture of Portland Cement Materials and Process

What is Portland cement process of Manufacturing,Dry and Wet

In the ball mill, particles crush to a fine powder and filled into bags The following flow sheet shows the details of the wet process in the manufacture of cement – The dry process for manufacturing In this process, the raw materials dried and ground to a fine powder by grinding mill The dry powder is then further blende and corrected for its right composition and mixed 21/05/2021 In dry and semidry processes for the manufacture of cement, raw materials are crushed and fed into the grinder in the correct proportions The raw material is dried and reduced in size to a fine powder in a grinder Dry DETAILED DRY PROCESS OF CEMENT Dry process The raw materials are crushed and fed in the correct proportions into a grinding mill, where they are dried and reduced in size to a fine powder The dry powder, called raw meal, is then pumped to a blending silo, and final adjustment is now made in the proportions of the materials required for the manufacture of cementLine diagram the dry process of cement manufacture of cement by dry process

Cement Manufacturing Process: How the Cement is Made?

All the cement plants set up after 1980 use the dry process for the manufacture of cement In this process, the calcareous materials such as limestone are crushed and stored in silos or storage tanks The argillaceous material such as clay is thoroughly mixed with water in a container known as the wash mill This washed clay is stored in basins Now, the crushed Manufacture Of Cement By Dry Process Flow Chart Dry process cement Britannica Other articles where Dry process is discussed: cement: Manufacture of cement: are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry powder, or ground dry and then manufacture of cement by dry processesFig Manufacture of Cement by Dry Process b) Wet Process The raw materials are firstly crushed and made into powdered form and stored in silos The clay is then washed in washing mills to remove adhering organic matters found in clay The powdered limestone and water washed clay are sent to flow in the channels and transfer to grinding mills Cement Manufacture Of Cement By Dry Process Wikipedia

Manufacture of Portland Cement: 3 Processes Concrete

The manufacture of Portland cement consists of the following three distinct processes: 1 Mixing 2 Burning 3 Grinding Process # 1 Mixing: Mixing can be done either by dry process or wetprocess ADVERTISEMENTS: (a) DryProcess: In this process, the raw materials, lime stone and clay etc are mixed in calculated proportions, crushed and ground in tube mills The 28/03/2018 Wet process Mixing of Raw materials in wash mill with 35 to 50% water Materials exiting the mill are called "slurry" and have flowability characteristics Size of the kiln needed for manufacturing of cement is bigger Raw material can be mixed easily, so a better homogeneous material can be obtained Fuel consumption is high ie,Difference between Wet and Dry process of cement – we Tools Dry Process Of Cement Manufacture Cement Manufacturing Process Civil Engineering Blog Aug 27, 2015 Following is the procedure of manufacturing cement by dry process using modern technology: Boulders of limestone upto 12m size are transported in huge dumpers upto 300kN capacity and dumped into the hopper of the crusher Get Price manufacture of manufacture of cement by dry processes

manufacture of cement by dry process wikipedia

Manufacture of Portland Cement Materials and Process Ordinary Portland Cement Constituents, Properties, Types, In the dry process these mixes are stored in silos; slurry tanks are used in the wet process The resulting material is known as slurry having 3540% water 3 Heating This is the main important step in the manufacture of OPC cement, the product About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators manufacturing processes of cement by wet and dry process 21/05/2021 In dry and semidry processes for the manufacture of cement, raw materials are crushed and fed into the grinder in the correct proportions The raw material is dried and reduced in size to a fine powder in a grinder Dry DETAILED DRY PROCESS OF CEMENT

Manufacture Of Cement Dry Process fredetpierrefr

all the cement plants set up after 1980 use the dry process for the manufacture of cement in this process, the calcareous materials such as limestone are crushed and stored in silos or storage tanks the argillaceous material such as clay is thoroughly mixed 5 Difference Between The Wet And Dry Process Of may 24, 2019 dry process 1 this method is adopted when Dry process The raw materials are crushed and fed in the correct proportions into a grinding mill, where they are dried and reduced in size to a fine powder The dry powder, called raw meal, is then pumped to a blending silo, and final adjustment is now made in the proportions of the materials required for the manufacture of cementLine diagram the dry process of cement manufacture of cement by dry processManufacture Of Cement By Dry Process Flow Chart Dry process cement Britannica Other articles where Dry process is discussed: cement: Manufacture of cement: are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry powder, or ground dry and then manufacture of cement by dry processes

Manufacture Of Cement By Dry Process Wikipedia

Fig Manufacture of Cement by Dry Process b) Wet Process The raw materials are firstly crushed and made into powdered form and stored in silos The clay is then washed in washing mills to remove adhering organic matters found in clay The powdered limestone and water washed clay are sent to flow in the channels and transfer to grinding mills Cement Manufacturing of Cement By Dry and Wet Process Although the dry process is the most modern and popular way to manufacture cement some kilns in the United States use a wet process The two processes are essentially alike except in the wet process the raw materials are ground with water before being fed into the kiln Read More Dry Process Of Cement manufacturing of cement dry processManufacture of Portland Cement Materials and Process Ordinary Portland Cement Constituents, Properties, Types, In the dry process these mixes are stored in silos; slurry tanks are used in the wet process The resulting material is known as slurry having 3540% water 3 Heating This is the main important step in the manufacture of OPC cement, the product manufacture of cement by dry process wikipedia

Difference between Wet and Dry process of cement – we

28/03/2018 Wet process Mixing of Raw materials in wash mill with 35 to 50% water Materials exiting the mill are called "slurry" and have flowability characteristics Size of the kiln needed for manufacturing of cement is bigger Raw material can be mixed easily, so a better homogeneous material can be obtained Fuel consumption is high ie,20/07/2020 P ortland cement is by far the most common type of cement in general use around the world This articles looks at the cement manufacturing process in 4 steps Step 1: Mining The first step of Cement manufacturing process is to quarry the principal raw materials, mainly limestone, clay, and other materialsCement manufacturing process: Stepbystep guide CCE l Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about 6 inchesCement Manufacturing Process Civil Engineering