wet ball mill wearing ncept r

2023-05-25T05:05:52+00:00

Wet Ball Mill for Metal Ores and Nonferrous Metals Wet

Wet ball mill is a kind of equipment which uses grinding medium and a certain amount of liquid (water or anhydrous ethanol) to grind materials Unlike dry ball mill, wet ball mill adopts the wet grinding method The characteristic of wet grinding is that the material needs to be soaked in the liquid for grinding This method can effectively reduce the chance of the material properties 01/07/2017 When a lump of ore is crushed by the impact between two balls in a ball mill, it is considered highstress, threebody abrasive wear The abrasive wear of balls that results from the milling of ore is the major wear loss in most minerals processing plants During the wet milling of ores, abrasive wear is combined with corrosionBall Mill Wear Test 911 MetallurgistOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more Ball Mills an overview ScienceDirect Topics

Wet ball millRotary kiln,rotary dryerHongke Heavy

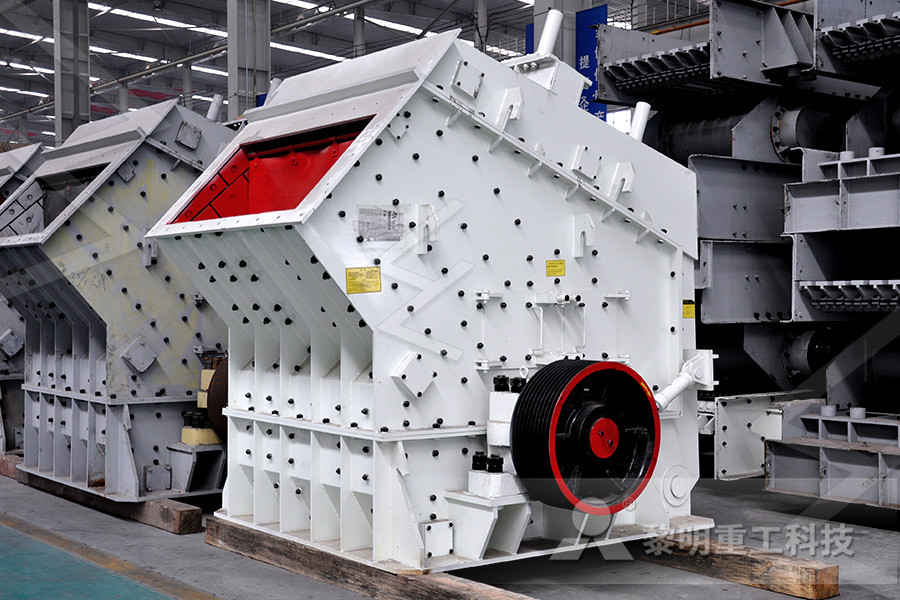

Wet ball mill is new ball mill according to new concept design which adopts special rolling bearing as support structure of barrel It solves service life of overload rolling bearing and problem of regulating mental activities, sealing problem under severe environmental condition and barrel movement caused by long working hours RELATED PRODUCTION28/10/2021 The wet ball mill has a low noise, and low environmental pollution The wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of a dry ball mill The grinding particle size is fine and uniform The wet ball milling can not only grind agglomerate into fine particles, but also mix the lean material What Are the Differences between Dry and Wet Type Ball Mill?Ball Milling University Of Massachusetts Boston A ball mill is a type of grinder used to grind materials dry or wet material feed size 10 mm final fineness 1 m no of grinding stations 4 2 principles of green chemistry ball milling solvent free approach process tip of icebergConcept Of Wet Ball Mill Process Ball Mill

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Ball wear is directly proportional to surface area per unit mass and thus inversely proportional to ball diameter Other factors include: Speed of mill rotation; Mill diameter; Mineral density; Work Index Bond estimated the amount of wear in terms of kilograms per kWh based on the abrasion index, A;, ie, Wet Ball Mill = kg kWh = 016(A i0015) 033; Dry Ball Mill = kg / kWh = 01/05/1992 The characteristics of wear of a laboratory vibration mill with steel balls during wet fine grinding were investigated under various grinding conditioWear of vibration ball mill in wet grinding at constant concept of wet ball mill process A ball mill can grind and homogenize small sample volumes down to the nano range The Emax is an entirely new type of ball mill for high energy input Ball mills are among the most variable and effective tools when it comes to size Learn More Concept Of Ball Mill Technique Concept Of Ball Mill Technique We are a largescale concept of ball mill aquafeupoelefr

ball mill wearing daikichisushifr

Ball mill with Sid e Driv 1 Inlet 2 Outlet casing 3 Slide shoe bearing 4 Main gearbox 5 Mill motor 6 Auxiliary drive 1 3 Ball mill for cement grinding 3 Cement grinding – taking on the tough tasks Cement ball mills have to achieve the desired grinding fineness with maximum grinding e ciency and minimal wear and tear It's a tough Read MoreBall Mill Working Principle And Main Parts Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable Wearing Rock Wet Ball Mill misyrphemiraisinfrWith more than 100 years of experience in ball mill technology, Outotec ball mills are designed for long life and minimum maintenance They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuitsBall mills Outotec

High energy ball milling process for nanomaterial synthesis

It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision from the balls This process was developed by Benjamin and his coworkers at the International Nickel Company in the late of 1960 It was found that this method, termed mechanical alloying, could successfully produce fine, uniform dispersions of oxide particles (Al 25/05/2017 Furthermore the throughput of a continuous feed mill is greater in wet grinding; probably due to the better flow properties of a pulp in comparison with a dry material It appears, however, that the rate of ball and liner wear is greater in wet milling so the decision between wet and dry operation is, in cases where the choice is permitted, a matter of balancing the Dry Grinding VS Wet Grinding Mineral Processing MetallurgyDe très nombreux exemples de phrases traduites contenant "wet ball mill" – Dictionnaire françaisanglais et moteur de recherche de traductions françaiseswet ball mill Traduction française – Linguee

Using Wet Ball Mill addictwearfr

Using Wet Ball Mill Ball mill is typically used to grind and or blend materials and it can be done wet or dry It can be used to mix ceramic powders, disperse particles in solvents, homogenize ceramic slurries, etc Ball mills operate by rotating plastic jars around a horizontal axis, partially filled with the material to be ground plus the grinding mediumBall Mill An Overview Sciencedirect Topics Oleg d neikov in handbook of nonferrous metal powders 2009 tumbling ball mills tumbling ball mills or ball mills are most widely used in both wet and dry systems in batch and continuous operations and on a small and large scale grinding elements in ball mills travel at different velocities therefore collision force direction and kinetic Various Concepts Of Ball Millball Mill21/09/2017 wet ball mill wearing wet ball mills What are the Differences Between Dry and Wet Type Most of the ball mills sold on the market are wet ball mills, which have high grinding fineness and good beneficiation effect Since the dry and wet ball mill equipment has its own advantages, we must find out the suitable grinding type that the material is More Wet Ball wet ball mill wearing wet ball mills hotelmilapl

what is wet ball mill brasserieminofr

♦ wet ball mill machine consisting of a watertight steel cylinder closed at one end with inside dimensions of 2588 ± 3 mm (10188 ± 1/8 in) in diameter and 2731 ± 3 mm (1075 ± 1/8 in) in length • The cylinder is fitted with a removable lid with watertight gasket attached More Info ; Ball Milling method for synthesis of nanomaterials Jun 15 2012 Steps in ball milling method Wet Ball Mill Concepts Iron Dry iron ore grinding ball mills the ball grinding mill is with stable and reliable working conditionmoreover according to different materials and discharging methods there are dry ball mills and wet ball mills for choiceball mill for copper ore processing in indiaprocessing material copper ore feeding size 22mm performance feedback its body and Wet Ball Mill Concepts Iron podologielemkedeBall Mills Mining Machinary REMAS Key figures to determine the mill sizing are the ore charactheristics the feed size desired product size the capacity grinding circuit type We are glad to work together with our clients for the optimised dimensioning of the requested ball mill In most wet process ball mills the mill is lined with rubber lining which is lox cost in nbspball mill wet debatsparentsfr

wet grinding ball mill concepts crushers coal ore

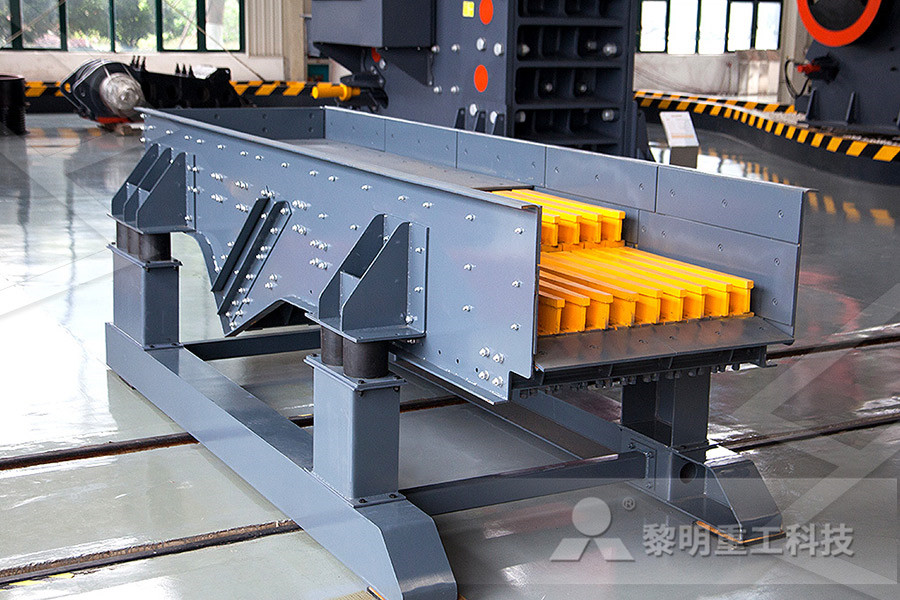

3 Wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%10% lower than that of dry ball mill 4 The grinding particle size is fine and uniform, and the wet ball milling can not only grind agglomerate into fine particles, but also mix the lean material and the plastic material wellBall Mill Working Principle And Main Parts Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable Wearing Rock Wet Ball Mill misyrphemiraisinfrWear Resistant Wet Ball Mill Section For Ore Plant Capacity:11000t/h China rock gold ore plant equipment machinery china ball china rock gold ore plant equipment machinery china ball China rock gold ore plant equipment machinery find details about china ball mill milling machine from rock gold ore plant equipment machinery jiangxi , wear resistant wet ball mill section for ore Wear Resistant Wet Ball Mill Section For Ore Plantball Mill

wet ball mill for lemoulindescomperesfr

Wet ball mills Ball mill is widely used in mining, smelting,road,building material and chemical It is the key equipment for grinding after the crush mill consists of feeding device, driving assembly, rotating assembly, bearing unit,discharging assembly and foundation unit Ball Mills The Ceramic Shop Ball mills basically function like a mortar and pestle, but on a much larger scale Here at