Cement Clinker Mill Production r

2019-05-14T17:05:38+00:00

Cement Clinker Production an overview ScienceDirect Topics

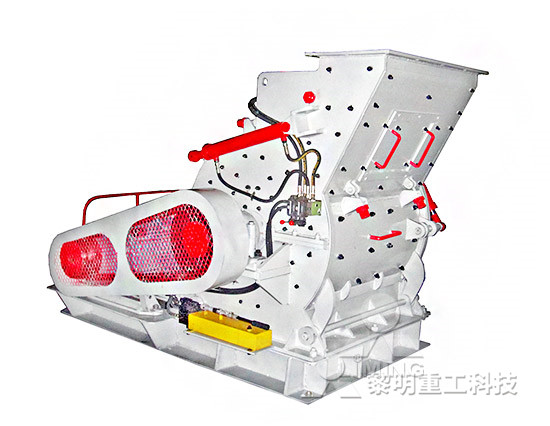

Used in the plant, limestone (55–60%), marl (35–40%), and copper slag (25–6%) are used as cement raw materials for the production of clinker The clinker is then finely ground in a ball mill grinding circuit together with a small amount (typically 4%) of gypsum to produce cement in the Turkey Trabzon Cement Plant ( Alp, Deveci, Süngün, 2008 )Cement Mill, Clinker Mill We provide various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/dCement Mill, Clinker Mill SBCCOCEMENTCement Production Process The cement production processes mainly include raw material crushing and storage, raw material proportioning and grinding, clinker calcination, clinker grinding, cement packing, etc Portland cement is the most widely used cement in our daily lifeCement Clinker Calcination in Cement Production Process

Clinker Production Clinker Plant Cement Plant Equipment

After the raw material is preheated and precalcined, the next step is clinker manufacturing In the rotary kiln, the carbonate is further rapidly precalcined and a series of solid phase reactions occur to form minerals in the cement clinker21/02/2019 Clinker (in cement industry) is transitional product in cement production Upon heating mixture obtained from limestone (about 75%) and clay (about 25%) partial melting occurs and clinker granules are formed Clinker and gypsum (about 5 %) are mixed and finely milled to obtain cement Gypsum control the setting properties of the cementCLINKER GRINDING IN CEMENT PRODUCTIONClinker cooler is also called cement cooler, which set behind the cement kiln for clinker cooling In cement plants, we usually adopt the rotary cooler and grate cooler for daily production Inside the cooler, hot clinker will direct contact with the cooled air Clinker Production Clinker Manufacturing Cement

Cement Clinker Quality Control During Clinker Production

During normal production process, the clinker is always calcined in a fixed temperature range According to the fluctuation of raw meal composition, the calcination temperature of clinker is generally between 1350℃ and 1450℃ If the temperature in the kiln is too low, it is easy to produce underfired clinkerCement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates approximately once every couple of secondsThe cement mill Understanding CementCement grinding mill is usually used in the clinker grinding processIt is the final stage in cement production which will directly affect the cement product quality, output and benefits Clinker particles, gypsum, and other materials in cement grinding machine will be ground together into fine powder to match the fineness of the finished productCement Mill Cement Grinding Machine AGICO Cement

Cement Production Line Cement Manufacturing Plant

The dry process cement production lines built by our company are economical and practical The whole production system runs stably and the power consumption is reduced by 20%30% Besides, the convenient construction process does not need too many workers, saving a lot of labor costs, greatly improving the benefits of customers Timely DeliveryThe following are several important factors affecting the cement clinker quality In the process of clinker production, strict control of these factors can ensure the production of highquality, highyield clinker 1 Lime Saturation Factor The lime saturation factor (LSF) is a ratio of CaO to other oxides, it is used to control the proportion Cement Clinker Quality Control During Clinker Production Gypsum Cement Clinker Mill To Improves The Production Gypsum Cement ClinkerMill To Improves The Production ProcessOf Clinker We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipmentcement clinker mill production autolavfr

Cement Mill Cement Grinding Machine AGICO Cement

Cement grinding mill is usually used in the clinker grinding processIt is the final stage in cement production which will directly affect the cement product quality, output and benefits Clinker particles, gypsum, and other materials in cement grinding machine will be ground together into fine powder to match the fineness of the finished productCement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product Clinker occurs as lumps or nodules, usually 3 millimetres (012 in) to 25 millimetres (098 in) in diameter It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement Cement clinker WikipediaRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Vertical Cement Mill Cement Clinker Grinding Equipment

Vertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement mill This vertical cement mill solves the technical A cement mill (or finish mill in North American usage) This is of advantage in that it maximizes the strengthproduction potential the clinker, because large particles are inert As a rule of thumb, only the outer 7 μm "skin" of each particle hydrates in concrete, so any particle over 14 μm diameter always leaves an unreacted core However, the lack of ultrafine particles can be a Cement mill WikipediaChangshan South Cement, China benefitted from a costsaving energy retrofit of its two clinker production lines with MC2x39No305F raw mill circulation fans Fan Retrofit at St Marys Cement Howden team retrofit an existing Induced Draft (ID) fan resulting in Cement Production Cement Howden

Vertical Cement Mill Great Wall

GRMK series Vertical cement mill have the ability completely to replace tube mill in the production of cement, for the reason, the cement specific surface area can be up to 3800 cm²/ g with stable and reliable quality 2 Reducing the power consumption of cement clinker preparation effectively According to the display of pulverized coal The dry process cement production line is composed of cement crushers, cement raw mill, cement kiln, cement cooler, cyclone preheater, cement silo, dust collector, etc AGICO offers cement production lines from 1000 TPD to 10000 TPDCement Production Line Cement Manufacturing Plant Cement grinding mill is usually used in the clinker grinding processIt is the final stage in cement production which will directly affect the cement product quality, output and benefits Clinker particles, gypsum, and other materials in cement Cement Mill Cement Grinding Machine AGICO

Sustainable Clinker and Cement Production by Using

Sustainable Clinker and Cement Production by Using Alternative Fuels and Raw Materials Our expertise Back Share: According to the International Energy Agency, the hightemperature process used in the manufacturing of cement accounts for around eight percent of the world’s anthropogenic carbon dioxide emissions The process also consumes up to three percent of Cement Manufacturing Process There are 4 stages of cement production that help maintain consistent raw material quality with minimal chemistry deviation, from quarry to silo to customer Step 1 The quarry Step 2 Crusher and preblending Step 3 Raw mill and kiln Step 4 Cement Manufacturing Process Thermo Fisher Scientific INCement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product Clinker occurs as lumps or nodules, usually 3 millimetres (012 in) to 25 millimetres (098 in) in diameter It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement Cement clinker Wikipedia

Vertical Cement Mill Cement Clinker Grinding Equipment

Vertical cement mill is a kind of vertical roller mill, also known as VRM cement mill, mainly used in the grinding production of cement clinker Our company absorbs the latest grinding technology from Europe and combines with the market demand of grinding industry to develop a new and improved vertical cement mill This vertical cement mill solves the technical Energy Consumption Benchmark Guide: Cement Clinker Production 8 • Blue Circle Cement’s Bowmanville facility replaced the inlet fan damper in its coal mill with a variable inlet vane damper The resulting reduction in power consumption saved the company $75,000 in annual energy expenditures • Essroc Canada Inc installed an electrical usage monitoring Energy Consumption Benchmark Guide: Cement Clinker ProductionThe cement ball mill is a kind of cement grinding millIt is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power enterprisesIt has the characteristics of strong adaptability to materials, continuous production, a large crushing ratio, and easy to adjust the fineness of Cement Ball Mill Cement Grinding Machine Cement Mill

Power consumption of cement manufacturing plant

The cement industry natural gas consumption is concentrated in the process of heating end use (about 90% of total gas consumption), which involves clinker production in large kilns In most cases natural gas is used as a supplemental fuel to coal, natural gas has the advantages of easier delivery, heat control, and there are other fuels can be used in cement rotary kiln, such as Now, taking the general production condition X = 020 as an example, the relative productivity K d of the mill with different feed particle sizes is calculated, as shown in table 1 table 1 From table 1 we can learn that if the particle size of the feed material is reduced from 25 mm to less than 2 mm, the mill output can be increased by at least 60%, which is relatively consistent with the How to Improve Cement Ball Mill Performance in Closed 12/05/2021 Minister of Industry, Investment and Commerce, Hon Audley Shaw, has informed that condensed milk and clinker (used in cement production) supplied within the Caribbean Community (CARICOM) “have [now] been afforded an additional layer of protection” Speaking in the 2021/22 Sectoral Debate in the House of Representatives on Tuesday (May 11), he noted More Protection For Condensed Milk And Clinker In CARICOM